Dielectric or Bragg Mirror and Its Applications

Mirrors and the Reflection of Light

To get a better understanding of dielectric mirrors aka Bragg mirrors, we need to understand the very basics of a mirror. Mirrors play an important role in many aspects of our life. From simple tasks such as grooming they help us safely change lanes while driving, assist dentists in cleaning our teeth, and help with complex imaging tasks in a space telescope! Mirrors reflect light or electromagnetic radiation, thereby allowing us to manipulate or divert light depending on a specific use case. Just as lenses can magnify, focus or collimate a light beam, mirrors can perform these functions in a variety of applications.

How Does a Mirror Work?

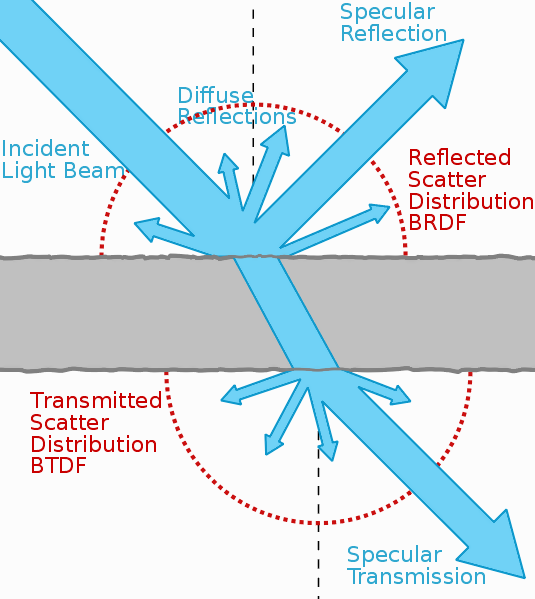

A mirror is a surface that reflects light back at an angle that is equal to the angle of incidence (AOI). This is called the law of reflection. Once a surface is made ‘optically smooth’ or polished such that the surface variations are microscopic in size, it will reflect light. Everyday objects around us do reflect light, but in a diffused manner since they are optically rough. In contrast, a smooth mirror surface reflects light in a specular manner, which makes it look shiny in contrast to a diffused surface.

Composition of a Household Mirror

To further understand the working of a mirror, let us consider a typical wall mirror we use every day. This mirror is comprised of a glass plate that is coated with a silver or aluminum film and has a protective back cover. The glass merely protects the thin metal film and has no other role in the mirror’s reflection. Silver films are used because silver not only has excellent reflection properties (95% reflectivity) in the visible light spectrum, it also reflects all colors of light equally. This is important because for normal household use we need the mirror coating to faithfully reflect all colors in the ambient light around us. In other words, we do not want a household mirror to reflect specific wavelengths of light. We want the mirror’s reflection to resemble what our eyes see.

However, most industrial, research, scientific and commercial applications require greater control of the reflected wavelengths of light. In such cases, a simple silver or aluminum mirror coating falls short of achieving the desired outcome. For instance, in a laser cavity there is a need for mirrors that have a reflectivity of 99.99% for a particular wavelength. In such applications, a special class of mirrors called dielectric laser mirrors need to be utilized in the laser cavity to generate enough gain and achieve lasing action. In contrast to a regular mirror, a dielectric mirror provides greater selectivity for reflection wavelengths and reflectivity. This makes them suitable for a wide range of applications such as lasers, head-up displays (HUDs), space technology, and many others.

What is a Dielectric Coating?

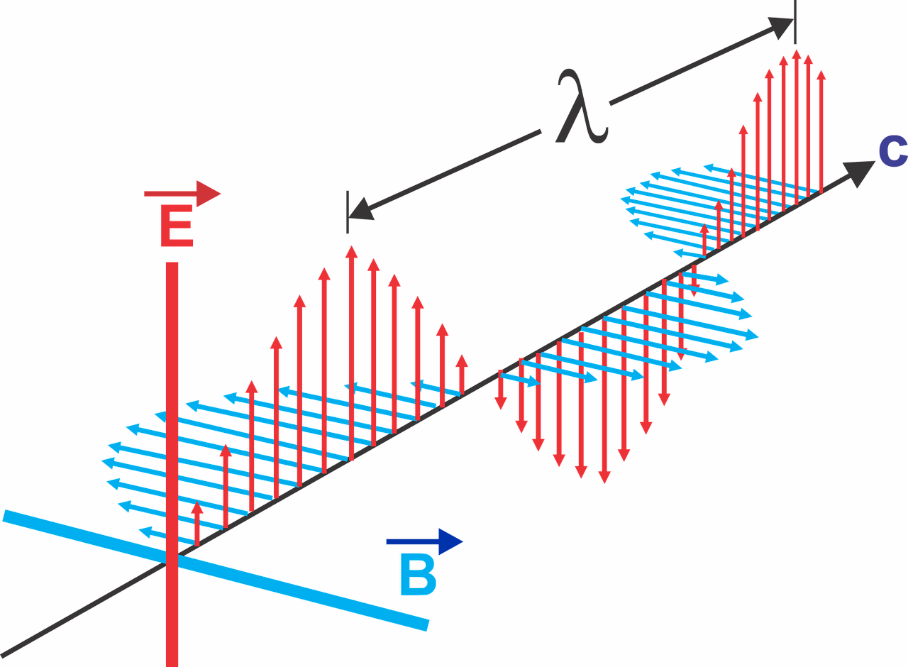

As the name suggests, a dielectric coating is made from a dielectric or a transparent optical material. Depending on the application, a single layer or multilayer coating of the dielectric is deposited on a substrate. Unlike metallic films, dielectric coatings rely on interference of light to alter the reflection properties of the substrate. A simple example is the multi-color pattern we observe from oil films on an asphalt road.

Light reflected directly off a thin film (oil, soap) can interfere with a secondary reflection, which could be in or out of phase. This results in constructive or destructive interference that is wavelength- and angle-dependent. This interference causes us to see some colors more prominently than others. The same principle applies in dielectric coatings. By controlling the thickness, refractive index, and the number of layers, the reflection properties of the composite film can be finely tuned to suit the application. For example, anti-reflection coatings can be designed which cut the glare that cause reflections in the visible (VIS) portion of the electromagnetic spectrum, but reflect the harmful ultraviolet (UV) component. Another example involves separating UV-VIS from IR wavelengths in imaging applications where broadband tungsten sources are involved.

Dielectric Mirrors

A single thin film coating is often insufficient to achieve high reflectivity or certain wavelength selections. In such cases, stacks of multiple thin film coatings are needed in order to obtain the desired spectral characteristics. Typically, these stacks are comprised of alternating thin film coatings of high and low refractive index dielectrics. When arranged in this manner, these mirrors are called dielectric mirrors or Bragg mirrors.

A multilayer stack is generally fabricated using advanced deposition techniques like electron beam deposition, ion assisted deposition (IAD), ion beam sputtering or plasma-based film deposition. From a design perspective, it is already evident that there is much greater control over the reflectivity using this approach as compared to single metallic coatings. The refractive index of the high index and low index layer, the thickness of thin film coatings, the number of dielectric pairs and the angle of incidence can all be tuned to achieve either narrowband or broadband wavelength properties depending upon the application.

Applications of Dielectric Mirrors

Laser Mirror

In a typical laser cavity, there is a requirement for mirrors with extremely high reflectivity in order to minimize optical losses. Losses increase the lasing threshold and lower the operating efficiency. Mirrors with high reflectivity (>99%) also result in high Q-factors and high cavity finesse, both of which result in better laser performance. Additionally, since lasers operate at a single wavelength, laser mirrors need to provide very high reflectivity at specific wavelengths. Considering these requirements, dielectric laser mirrors are the best choice for reflectors in laser resonators.

Since, many laser systems also require mirrors that can withstand high optical power thresholds, conventional mirrors are unsuitable for these applications, as they will be damaged. Again, dielectric mirrors are best suited for such applications as they can be customized to withstand very high optical flux.

Dichroic Mirror

Several applications require wavelength selectivity for more than one wavelength. For instance, in projection systems mirrors are needed for color mixing to obtain RGB colors in the projected image. In such applications, a white light source is split into 3 color channels using dichroic mirrors, modulated by the corresponding LCD panels and combined using a trichroic prism to realize color projection.

Hot Mirror

Similar to a dichroic mirror, there are applications which require wavelength selection between the visible and infrared (IR) spectrum. The most common application of a hot mirror involves reflecting IR radiation from optical paths to minimize the impact of heat. When using broadband light sources that emit wavelengths from the visible all the way up to IR, generation of heat is inevitable. These mirrors are increasingly used in cameras to reflect IR wavelengths and only pass visible light, thus enabling high contrast photography, especially in cases that require long exposure times. EMF’s hot mirrors provide a versatile approach for heat control. Mirrors can be designed to operate in different spectral bands, over different angles of incidence (AOI) and come in a variety of shapes and sizes e.g. square or round.

Cold Mirror

In contrast to the hot mirror, a cold mirror only reflects visible light and lets infrared (IR) radiation pass through. An interesting application of cold mirrors is in Head-Up Displays (HUDs) like the ones used in cars and trucks, flight simulators and airplane cockpits. A HUD utilizes a broadband light source for its display, which typically has an IR component that can cause heating. Here, a cold mirror reflects the visible light component needed for the display and transmits the IR component. This cuts out any unwanted reflected heat from damaging the optical components within the HUD assembly.

EMF’s cold mirrors are known for their precision, accuracy and reliability. They are an integral part of HUD assemblies found in some of the leading makes and models of cars in the US and around the world. EMF has shipped over 700,000 cold mirrors to a global automotive components manufacturer without a single incident of a field failure.

Choosing the Best Dielectric Mirror

The choice of dielectric mirrors depends on the following functional and operational specifications of your application:

- Wavelength characteristics: Do you need a mirror to combine different colors or split them? Do you need to select one wavelength band and/or reject another? Coming up with a desired reflection spectrum for the mirror is the first step towards finding a mirror best suited for your application.

- Mirror surface: Surface roughness is another criterion that needs to be considered. Does your application require a mirror with a flat, spherical or cylindrical surface?

- Reflectivity: Do you need 90% (household mirrors) or 99% (specialized industrial mirrors) or even 99.99% (laser mirrors) reflectivity? 90% reflectivity will not be enough for laser mirrors but it could work for a cold mirror used in HUDs. There will generally be a trade-off in terms of wavelength characteristics and reflectivity depending on the complexity of the application.

- Angle of Incidence (AOI): Again, this depends on the application and is a very important design criterion. A mirror designed to reflect 99.99% of light of a certain wavelength at 0o angle of incidence, will not achieve the same reflection at 45o. A HUD typically requires a 45o angle of incidence, whereas a linear laser cavity may require an angle of incidence of 0o.

- Operating environment: Where is the mirror being used? Inside a camera, a car or will it be mounted on a satellite? The operating environment will dictate the choice of substrate. The mirror needs to be designed to operate efficiently whether there is high humidity or high optical flux, or if it needs to be scratch resistant. These constraints will eventually determine the choice of the optical material.

- Tolerance: How precise do each of the above criteria need to be? This not only depends on the application but may also be influenced by practical aspects like balancing cost and performance. Size, thickness, spectral and angular tolerances need to be considered.