At Omega Optical, scale is a specialty

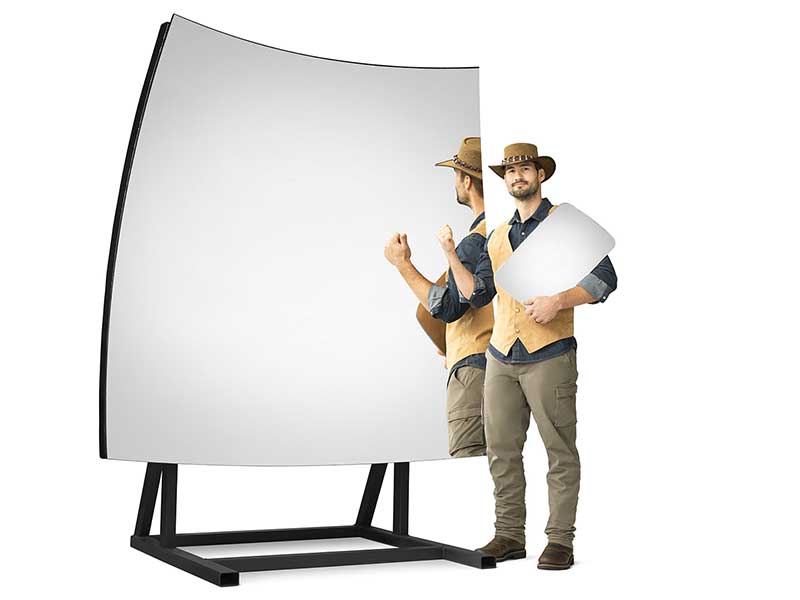

Our advanced large-aperture coating systems can deposit precision optical coatings across wavelengths from UV through IR on components up to 40 inches in diameter—and in some cases, up to 108 inches.

These same systems can also be reconfigured for high-volume runs of smaller optics, such as 2-inch squares, allowing for both flexibility and throughput within a single production environment.

- Experience handling and shipping large optics up to 5,000 lbs

- Custom coating room for the handling of large materials

- Experienced large optics program engineers and technicians

- Multi-layered dielectric coatings up to 40 inches in diameter and up to 108 inches in our largest coater.

- Coating uniformity modeling

- Measurement/Metrology capability for large optics

- Using Optical-grade glass, metals & ceramics, polymers & flexible substrates

Omega also delivers diamond-like carbon (DLC) coatings for infrared optics, providing superior durability, abrasion resistance, and environmental protection. IR and DLC options can be added to your custom large-scale coating order.

Our custom-engineered DLC coating chamber supports IR materials such as:

- Silicon (Si)

- Germanium (Ge)

- Zinc Sulfide (ZnS)

- Zinc Selenide (ZnSe)

- Chalcogenide glasses

Explore the Features

Large-Scale Coating Expertise in Ithaca, NY

As part of the Omega Optical family, our Ithaca, New York facility has specialized in custom and high-volume thin-film coatings since its inception. The facility’s versatility supports applications from automotive and display systems to instrumentation, satellite communications, protective face shields, power cells, and lighting.

Purpose-Built for Large Optic innovation

History

Originally established in 1987, the Ithaca facility spans 44,000 square feet, designed from the ground up to meet the demanding requirements of precision optics manufacturing. Over the decades, our teams have expanded both the breadth and capacity of our coating technologies to meet the evolving needs of OEMs, research institutions, and advanced manufacturers worldwide.

Large Substrate Sizes

Our largest chamber can coat single parts up to 108 inches in size.

Substrate Types

We coat on typical optical glasses, ceramics, composites, plastics, acrylics, and metals.

Applications

Our facility’s versatility supports applications from automotive and display systems to instrumentation, satellite communications, protective face shields, power cells, and lighting.

Key supporting capabilities

Solution

Design & Engineering

Our commitment to finding the right solutions for difficult problems means that we are capable of doing what other engineers cannot. Some say we bend physics and solve the unsolvable. Can we? Maybe. What we know we can do is this: We ask questions and we dig, because sometimes the solutions people believe they need only scratch the surface.

Solution

Grating Manufacturing

We have the diffractive optics trifecta of multiple Ruling Engines, Holographic Mastering, and Lithographic exposure to create diffractive elements. Our in-house design and manufacturing processes provide standard or custom gratings for a range of applications, in both Original and Replicated formats.

Solution

Metrology & Quality Assurance

We believe you cannot confidently make what you cannot measure, and therefore have invested in standard and custom metrology and inspection stations. Certified ISO 9001:2015. Lean manufacturing, including 6 Sigma methodologies and approaches to problem solving.

Solution

Research & Development

We keep one eye on the horizon for the needs of tomorrow. We are Trusted Collaborators with a passion for innovation.